What is Helium Bombing?

Helium bombing is the process of exposing a part to helium at an elevated pressure for an extended period. This forces helium into the part if a leak exists, preparing the part for a subsequent helium leak test. Once the part is bombed, the helium in the part can now be drawn out and measured using a helium leak detector to confirm the presence of a leak. The main goal of helium bombing is to identify leaks in parts that might otherwise go undetected, ensuring high-quality standards in parts requiring hermicity.

How is Helium Bomb Leak Testing Performed?

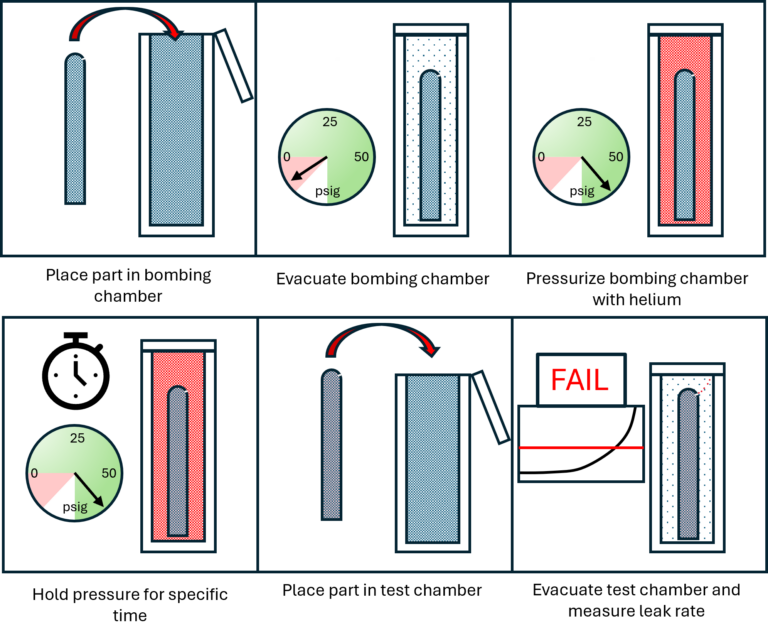

This is a two-step process. First, the parts are placed into and sealed in a chamber. This chamber is then evacuated to remove as much ambient air as possible so that when helium is introduced its concentration is high. The chamber is then pressurized with helium and held for an extended period to allow helium to slowly “leak” into the part. This bomb time is determined beforehand and can be from a few minutes to a few hours.

Second, when the parts come out of the bombing chamber, any leaking parts will have some helium inside of them. These bombed parts are promptly placed into a vacuum chamber and tested for leaks using a helium leak detector connected to the vacuum chamber.

How Long Does a Part Need to Be Bombed?

Several factors affect the duration of helium bombing and the feasibility of using it to leak test parts. These factors include part size, internal volume, the size of the leak being detected, and whether the part can tolerate vacuum and elevated pressure. For small parts with low internal volume, such as the size of a pencil eraser or a foam earplug, helium bombing might only take 15 to 30 minutes at 80 psig. For larger parts, such as a cylinder 3 feet long and 6 inches in diameter, helium bombing might need to be conducted for 12 to 24 hours. Bombing time increases for larger parts or when smaller leak rates are being detected.

The Role of Air in Helium Bombing

When a part undergoes helium bombing, helium is added to the air already within the part which raises the overall pressure and helium concentration within the part. Since the goal is to detect small leaks, any part with a leak (at or near the design leak limit), will allow only a small amount of helium in it. This small amount of helium diluted into the air already in the part will cause an observed leak signal that is only a fraction of the true leak rate. Having a higher concentration makes helium testing easier but the only way to increase concentration is to increase the helium pressure and/or duration of the bombing cycle which impacts throughput.

Why Choose Helium Bombing for Leak Testing?

Helium bombing is chosen for leak testing for two primary reasons:

- A large quantity of small parts needs to be tested with the high sensitivity and throughput that helium bomb testing facilitates.

- A part requires the sensitivity of a helium leak test, but there is no other feasible method to introduce helium into the part.

For larger parts, it is often more effective to find ways to introduce helium during assembly or use direct injection methods instead of relying on helium bombing.

Want to find out if helium bombing is the right choice for your project? Let’s discuss your specific needs!

How Can the Test Be Optimized?

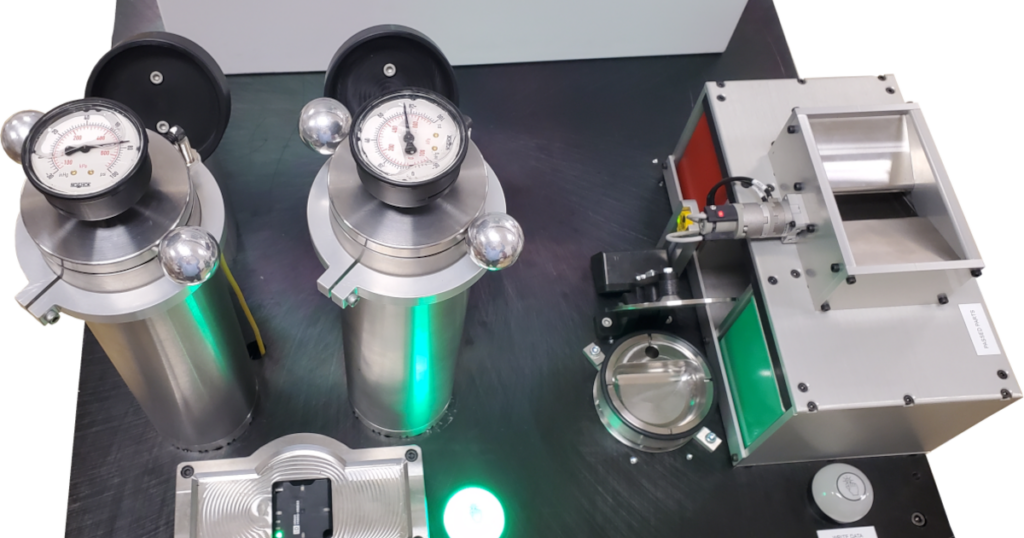

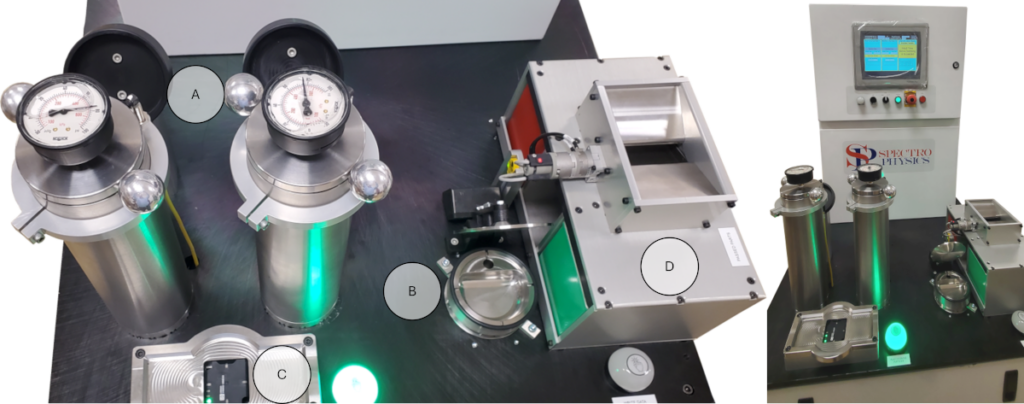

In practice, helium bomb leak testing is generally most effective for small parts. With multiple chambers, several hundred small parts can be bombed at once. These small parts require only a few minutes of pressure exposure, allowing for a faster process. Having multiple chambers allows parts to be bombed while others are leak-tested simultaneously. Typically, the parts are tested in small batches, reducing the overall testing time. Once bombed, parts are leak-tested in a vacuum chamber connected to a helium leak detector, which takes only a few seconds to determine if a batch passes or fails.

However, when a batch fails, it’s challenging to determine which part caused the failure, so all parts in the batch need to be handled again. Since the helium leak test removes helium from the parts, testing them again could result in a false pass as some helium may have already escaped. To minimize scrap, parts can be tested individually, but they must be bombed again prior to retesting.

Helium Bombing Highlights

Helium bombing is ideal for introducing helium into parts that do not already contain the gas. It’s particularly useful for small parts, where internal volume, part size, and leak rate are critical factors. As the size of the part increases or the leak rate decreases, the bombing time will increase. Understanding these factors ensures the effectiveness of helium bomb leak testing in detecting even the smallest leaks.