What is a Pressure Decay Leak Test?

A pressure decay leak test is a widely used method for identifying leaks in parts by observing changes in pressure. During the test, a part is pressurized, and the pressure is monitored over a specific time period. If the pressure drops below a predetermined threshold during the test, the part is deemed to have a leak and is rejected. This non-destructive leak detection method is common in various industries, ensuring that tested parts can still be used for their intended purpose.

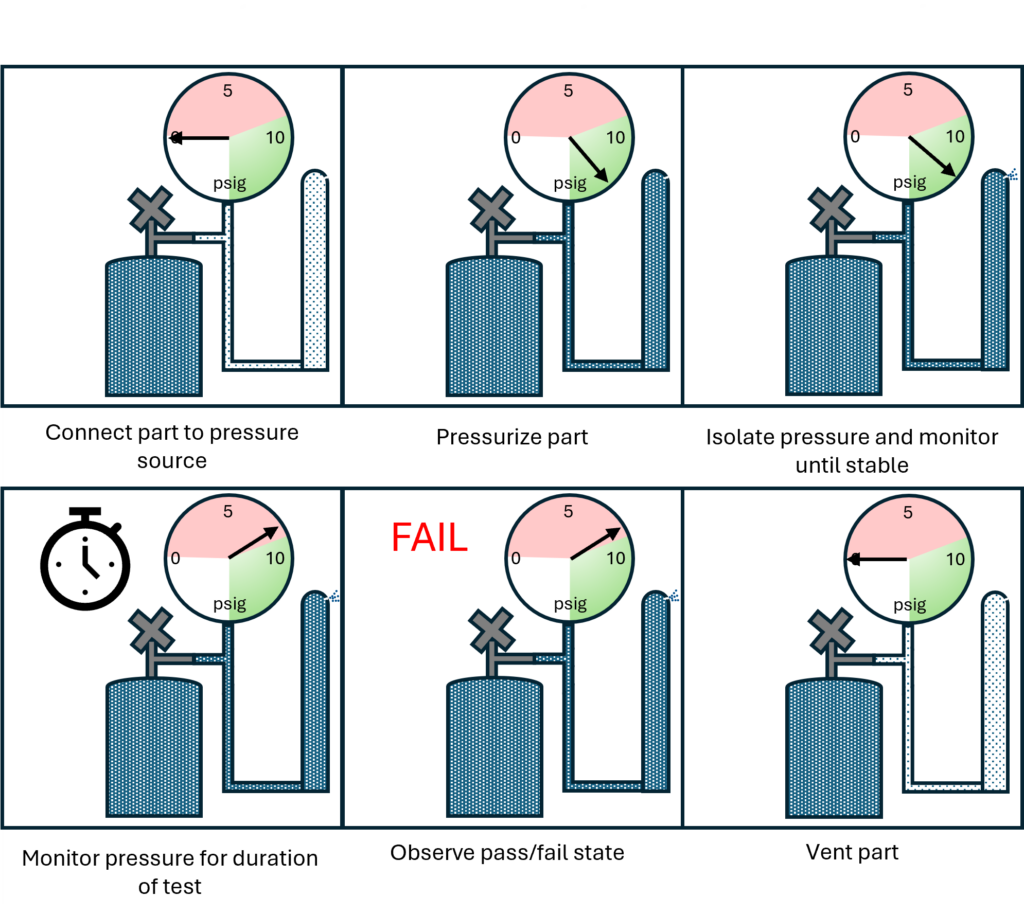

How to Perform a Pressure Decay Leak Test?

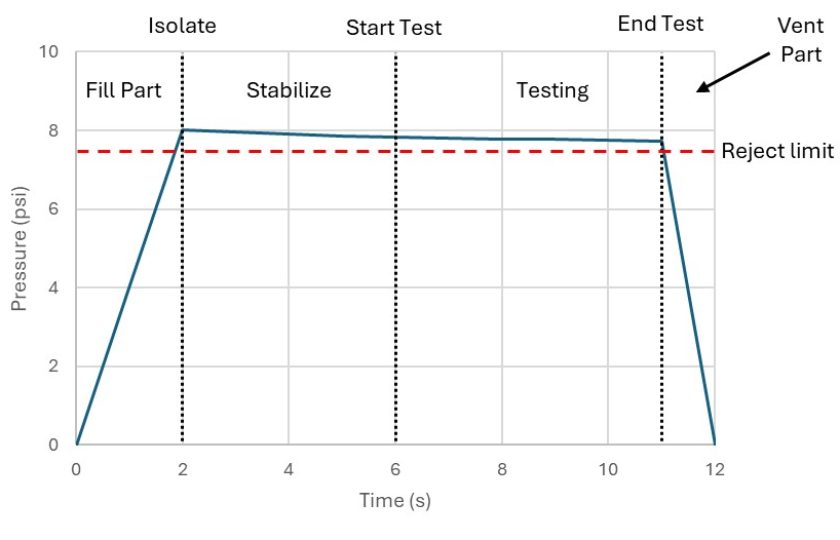

To conduct a pressure decay leak test, you first connect the part to a pressure source and apply pressure. The part must be linked to a pressure transducer or gauge to monitor the pressure. After pressurizing the part, it is allowed to stabilize for a short period. Once stabilized, the part is isolated from the pressure source, and pressure is continuously monitored. If the pressure drops below the reject limit during the test, the part fails.

To verify the test method and equipment functionality, a calibrated air leak standard (or leak orifice) can be used with a known good part. If the good part fails under the same test conditions, the equipment and procedure are confirmed to be working properly.

Do you need a new leak or a calibration on a leak you already own?

Explore our air leak standards for pressure decay testing and controlled air flow applications.

How to Calculate the Leak Rate?

The leak rate in a pressure decay test is calculated based on the volume of the part and the change in pressure over time. For example, let’s examine a real-world scenario such as a rapidly deflating tire. We will ignore the fact that the leak rate decreases as the tire deflates. Using the formula Leak Rate = Change in Pressure x Volume / Time, you can estimate the leak rate.

Assume the tire has a volume of 35 liters, an initial pressure of 2068 mbar (30 psig), and it goes flat in 5 minutes (300 seconds). The leak rate can be calculated as:

Leak Rate = 2068 mbar x 35 L / 300 s = 241.3 mbar L/s.

This shows how pressure decay tests quantify the size of the leak based on the pressure drop over time.

Pros and Cons of Pressure Decay Leak Testing

Pros:

- Cost-Effective: Unlike trace gas leak testing, pressure decay leak testing primarily uses clean, dry compressed air, which is inexpensive and readily available.

- Low Equipment Cost: No need for expensive vacuum pumps or mass spectrometers (used in helium leak detection).

- Non-Destructive: Parts remain dry and unaltered, unlike the submersion required in bubble leak testing.

- Flexible Applications: Even flexible parts can be tested as long as they can withstand the introduced pressure.

Cons:

- Temperature Sensitivity: As pressure is affected by temperature, environmental temperature changes can influence the sensitivity of the test.

- Test Duration for Larger Parts: The larger the part, the slower the pressure decay, meaning longer test times for larger components.

- Leak Location Not Identified: While pressure decay leak testing can detect the presence of a leak, it does not indicate the exact location of the leak.

- Limited Sensitivity: The method is effective for detecting leaks as small as 1E-3 mbarL/s or larger.

How Long Does the Test Take?

The duration of a pressure decay leak test depends on various factors such as part size, applied pressure, and the size of the leak. Smaller parts test more quickly, while larger parts take longer. The test will also be faster when higher pressure is applied. However, testing for smaller leaks typically requires a longer duration.

Alternatives Leak Testing Methods

- Vacuum Decay Testing: Similar to pressure decay testing, vacuum decay testing involves evacuating the part instead of pressurizing it. It is not affected by temperature changes like pressure decay testing and can detect smaller leaks due to the higher sensitivity of vacuum gauges.

- Tracer Gas Leak Testing: This method uses a tracer gas (such as helium or hydrogen) to detect leaks. Tracer gas leak testing can identify both the presence and the location of a leak. It is capable of detecting smaller leaks than pressure or vacuum decay tests. Variations of tracer gas methods such as sniffer or spray testing can be used to identify the location of the leak.

Pressure Decay Leak Testing Highlights

Pressure decay testing offers a robust, cost-effective method for detecting leaks, particularly large ones. While it excels in general leak detection, it has limitations such as its sensitivity to temperature changes and inability to pinpoint leak locations. For smaller leaks, longer testing times may be required, and the test is best suited for parts that can handle the applied pressure.

Want help finding the best system for your leak detection needs?