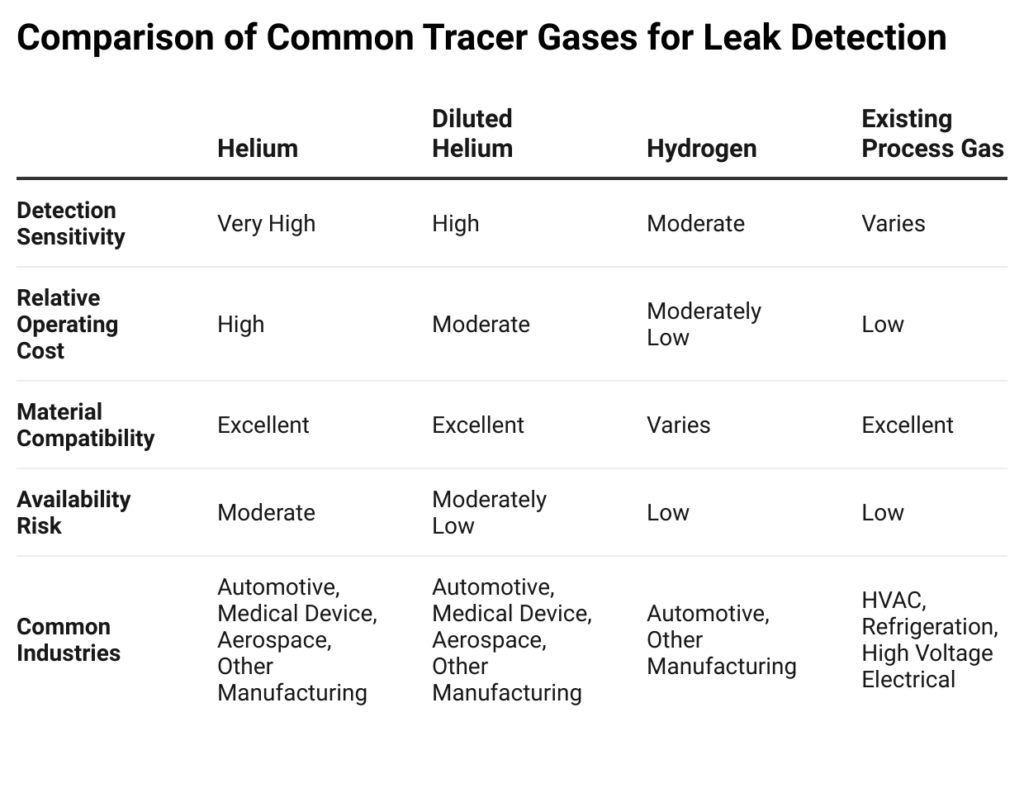

The tracer gas chosen for leak detection plays a crucial role in ensuring the quality and safety of various systems, from HVAC and refrigeration to other manufacturing processes. Understanding which gas to use for leak detection can significantly improve the efficiency and accuracy of detecting even the smallest leaks. In this article, we’ll explore the top tracer gases commonly used for leak detection, their benefits, and the best practices for choosing the right gas for your testing needs.

Why Helium is the Best Tracer Gas for Leak Detection

When it comes to tracer gas for leak detection, helium stands out as the preferred choice for most applications. Here’s why:

- Smallest Atomic Size: Helium is the smallest element, allowing it to easily pass through even the tiniest leak paths. This makes it the go-to gas for detecting the smallest leaks that other gases might miss.

- Easily Detected: Specialized helium leak detectors are readily available, allowing for precise detection of helium even at very low concentrations.

- Low Background Presence: Helium is naturally present in the atmosphere at only around 5 ppm, making helium leaks easier to distinguish from normal low background levels.

- Inert Nature: As an inert gas, helium doesn’t react with the materials being tested, ensuring that it won’t interfere with the integrity of the part.

- Safe and Non-toxic: Helium is non-flammable and non-toxic, posing minimal safety risks apart from the handling of pressurized gas and possible oxygen displacement.

- Low Detection Limits: Helium can detect leaks as small as 10-12 mbarL/s, offering high sensitivity for leak detection.

Limitations of Using Helium for Leak Detection

While helium offers unmatched sensitivity and reliability for leak detection, it’s not without its challenges:

- High Permeability: Due to its small atomic size, helium can permeate through certain materials—like some elastomers and plastics. This can lead to false positives or unstable test results if the material’s susceptibility to helium permeation isn’t carefully considered.

- Cost and Availability: Helium prices have been volatile due to supply constraints. In high-volume testing environments, this can significantly impact operational budgets.

- Non-renewable Resource: Helium is a finite resource extracted from natural gas fields. Overuse contributes to long-term sustainability concerns.

- Detection Equipment Sensitivity: While helium detection systems are highly sensitive, this can be a double-edged sword. Ambient helium contamination (e.g., from systems leaks or the production and testing process) can interfere with test accuracy if proper background control isn’t in place.

Versatility in Leak Detection with Helium

Helium is not only effective but also versatile in its application. Here are the most common methods for using helium in leak detection:

- Spray Testing: Helium is sprayed on the outside surface of parts, using a helium leak detector to sense any helium entering through leaks in the parts.

- Sniffing: Helium is introduced inside the part. A sniffing probe attached to the leak detector is slowly passed over potential leakage points where any helium leaking out is identified.

- Hard Vacuum Testing: The part to be tested containing helium is placed into a vacuum chamber. The chamber is evacuated and connected to the helium leak detector, allowing for highly sensitive detection of even the smallest leaks.

For a more detailed look at these methods and how they work, check out a more in-depth overview in our What is Trace Gas article.

Helium Bombing: A Specialized Method for Leak Detection

In some cases, it can be difficult to introduce helium into a part before performing the leak test. Helium bombing is a specialized method that may overcome this challenge.

What is Helium Bombing?

Helium bombing involves exposing a sealed part to high-pressure helium for a specified period. This forces helium into the part through any leaks present within the part. After the exposure, the part is placed into a vacuum chamber, and a helium leak detector is used to identify any escaping helium. If the part has a leak, some of the helium that was forced into the part during bombing will escape, and the detector will measure it.

For a more detailed look at helium bombing, check out our dedicated article: What is helium bombing for leak testing?

Diluted Helium: A Cost-effective Alternative

While helium is the top choice, its cost can be a concern, especially in large-scale testing. Diluted helium—a mixture of helium with nitrogen or air—can provide a cost-effective solution while maintaining high sensitivity.

Why Use Diluted Helium?

- Cost Savings: Pure helium can be expensive, particularly in regions with supply shortages. Diluting helium can reduce gas costs significantly, especially in large-scale testing environments. Using a 10% helium concentration, for example, can reduce costs by up to 90%.

- Sufficient Sensitivity: While not as sensitive as 100% helium, the 10% mix still easily supports the detection of leaks down to 10⁻⁷ mbar·L/s, which is suitable for many commercial and industrial uses.

- Same Detection Equipment: Helium mass spectrometer leak detectors can be calibrated to work with diluted helium, meaning no new equipment is necessary.

- Supply Chain Risk Reduction: Using diluted helium helps mitigate the impact of helium shortages

Hydrogen as an Alternative Tracer Gas

Hydrogen is another viable tracer gas for leak detection. Here are some reasons why hydrogen might be suitable for specific applications:

- Small Size: Hydrogen is the second smallest element after helium and can also pass through tiny leak paths.

- Easily Detected: Leak detectors tuned to detect hydrogen are widely available.

- Lower Cost: Hydrogen is less expensive and more readily available than helium, making it an attractive option for larger projects.

- Moderate Detection Limits: Hydrogen leaks as small as 10-7 to 10-6 mbarL/s can be detected.

However, there are some challenges with hydrogen:

- Flammability: Hydrogen is highly flammable. To mitigate the risk, a diluted hydrogen mixture (usually 5% hydrogen and 95% nitrogen) is often used.

- Permeation: While not as permeable as helium, hydrogen can still pass through certain materials, making detection a bit more difficult in specific cases.

Process Gases as Tracer Gases

Another option for tracer gas for leak detection is to use process gases already present in your manufacturing or production environment. These gases, such as refrigerants or sulfur hexafluoride (SF6), can provide convenient and cost-effective alternatives. Common examples include:

- Refrigerants (R-134a, R-410A, R-290, R-600, etc.): Used in HVAC and refrigeration systems; easy to integrate as tracer gases in service testing.

- Sulfur Hexafluoride (SF₆): Common in high-voltage electrical equipment like transformers and circuit breakers.

- Battery Electrolyte Solvents* (e.g., dimethyl carbonate, ethyl methyl carbonate): Found in lithium-ion batteries; useful for leak testing during battery cell assembly. These are liquids under normal conditions but vaporize when exposed to vacuum.

Using these gases can be beneficial because:

- Cost-Effective: No need to purchase additional gases like helium.

- Availability: Since these gases are already in use, they are readily available for testing.

- Familiarity: Workers are typically trained in handling these gases, making integration of leak detection smoother.

How Are Process Gases Detected for Leak Testing?

Many of the gases already used in manufacturing can be detected with leak detectors that feature mass spectrometers, typically a quadrupole mass spectrometer. These detectors are specifically tuned to detect the gas being used, ensuring that even low concentrations are identified accurately.

Key Takeaways for Choosing the Right Tracer Gas for Leak Detection

When selecting the right tracer gas for leak detection, the following factors should guide your decision:

- Size of Leak: Helium is best for detecting small leaks, while hydrogen is more appropriate for larger leaks.

- Safety Concerns: Both helium and diluted hydrogen mixtures are safer options compared to pure hydrogen.

- Cost: If helium is too expensive, diluted helium or process gases can be cost-effective alternatives.

- Material Considerations: Consider the permeability of the materials being tested and whether the tracer gas may leak through them.

Ultimately, choosing the best tracer gas for leak detection depends on your specific needs and constraints. Whether you opt for helium, hydrogen, or another gas, having the right tools and knowledge will help you achieve accurate and efficient leak detection.

Ready to Optimize Your Leak Detection Process?

If you’re looking for expert advice on selecting the right tracer gas for leak detection or need help with your specific leak detection project, we’re here to help! Contact us today to discuss your unique application, and our team of professionals will guide you to the best solution.