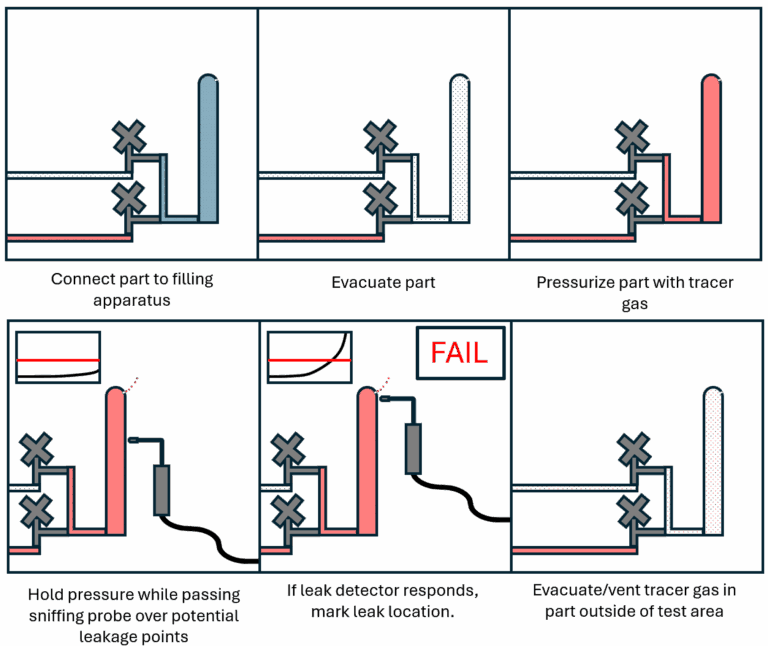

A sniffer test is a leak detection method that uses a tracer gas to locate and identify leaks in pressurized systems. Most commonly, the tracer gas is helium or hydrogen. During a sniffer test, the component or system is pressurized with the tracer gas, and a sniffer probe, connected to a leak detector, is passed near potential leak points. The leak detector then picks up any escaping tracer gas, allowing for accurate identification of leak locations.

The helium sniffer test is particularly popular due to helium’s small atomic size and inert properties, making it ideal for detecting microscopic leaks.

What Gases Are Used in a Sniffer Test?

Helium

The helium sniffer test is the most sensitive method for detecting small leaks. Helium is the smallest inert gas atom, which allows it to pass through even the tiniest leak paths. It is non-reactive, non-toxic, and safe to use in industrial environments. The helium leak test sniffer method is widely used in aerospace, automotive, refrigeration, and HVAC applications for its high precision.

Hydrogen

Hydrogen is also used as a tracer gas in sniffer testing. However, because pure hydrogen is highly flammable over a wide range of concentrations, it is typically used in a diluted mixture of 5% hydrogen and 95% nitrogen, commonly known as forming gas. This non-flammable mixture makes it safe for industrial use. While hydrogen can effectively detect leaks, the dilution limits its sensitivity, and higher background interference compared to helium makes it less ideal for detecting extremely small leaks.

Refrigerants

In HVAC systems, refrigerants themselves can be used for sniffer testing. Because these systems are already pressurized with refrigerant, it makes sense to use the same gas for leak detection.

Interested in learning more about tracer gases and how to choose the best one for your application?

Check out our detailed guide: Top Tracer Gases for Leak Detection: What to Use & Why.

Equipment Required for a Sniffer Test

To perform a successful sniffer test, the following equipment is essential:

- Leak Detector: This device is calibrated to detect the specific tracer gas used (helium, hydrogen, or refrigerants). Some detectors are gas-specific, while others can handle multiple gases with the correct settings.

- Sniffer Probe: Connected to the leak detector, this handheld device is manually guided along the surface of the component to detect escaping tracer gas at potential leak points.

- Calibrated Leak Standard: Also known as a sniffer leak standard, this reference tool emits a known amount of tracer gas and is used to verify that the leak detector is accurately calibrated. It ensures consistent performance and helps maintain the reliability of sniffer test results.

- Automated Sniffer Systems: In high-volume manufacturing, robotic sniffers integrated with PLC systems can perform rapid, repeatable sniffing. These systems are especially useful for helium sniffer tests in the production of refrigeration units and similar equipment.

Boost your test accuracy with expert-calibrated solutions.

Explore our calibrated leak standards and recalibration services — trusted by manufacturers for precision, reliability, and tailored leak testing solutions.

Looking for sniffer-specific calibration tools?

Explore our sniffer leak standards for helium, hydrogen, and refrigerant testing.

Advantages of the Sniffer Test Method

The sniffer test offers several key benefits:

- Pinpoint Leak Location: Unlike vacuum or pressure decay tests, the sniffer test can identify the exact source of the leak.

- Cost-Effective: Sniffer testing doesn’t require vacuum chambers or pumps, reducing equipment and operating costs.

- Versatile: It works with various tracer gases and is suitable for a wide range of part sizes and shapes.

- Simple Setup: Especially in field applications or maintenance, sniffer tests can be done quickly and easily without complex machinery.

In industries like automotive manufacturing, sniffer testing is often used to validate the integrity of air conditioning systems and fuel delivery lines. In aerospace and medical device sectors, where even microscopic leaks can be critical, the helium leak test sniffer method is a standard for high-precision testing.

Limitations of Sniffer Testing

Despite its advantages, sniffer testing has some drawbacks:

- Higher Gas Usage: Large components require more tracer gas, increasing cost—especially when using helium.

- False Positives: Gas may drift from the actual leak point, making it harder to identify the exact location.

- Time-Consuming: Each potential leak point must be individually checked, making the process slower for complex parts.

- Detection Sensitivity: For extremely small leaks, the helium leak test sniffer method is best, but only when proper gas concentration and equipment calibration are maintained.

- Testing Large Leaks: In some cases, if the leak is too large, helium may escape too quickly and reduce detection accuracy. Blocking large leaks before proceeding may be necessary.

Sniffer Testing Best Practices

To get the most accurate and efficient results from a sniffer test, follow these industry best practices:

Minimize Ambient Airflow

Perform testing in an area with minimal airflow. Air movement can disperse tracer gas, leading to false positives or missed leaks. If a leak has already been detected and plugged, temporarily venting the area can help clear residual tracer gas and improve accuracy.

Purge Before Testing

Before beginning a helium sniffer test, evacuate or purge the component with the tracer gas. This ensures that internal air doesn’t block gas flow, especially in small, intricate channels where trapped air could prevent the tracer gas from reaching the leak point.

Use Bottom-Up Testing

Helium and hydrogen are lighter than air, so leak detection should begin from the bottom up. This approach helps identify leaks at their actual source rather than misinterpreting the location due to tracer gas migration. If a larger leak is detected near the bottom of the component, it may need to be temporarily sealed to ensure accurate testing of the remaining system.

Move the Probe Slowly

For small or hard-to-find leaks, move the sniffer probe slowly and methodically. Leaks may not trigger the detector instantly, and moving the probe too quickly can result in missing the exact source. Pay close attention to changes in detector response even a few seconds after passing over a location.

Validate Part Fill

Periodically connect a calibrated sniffer leak standard directly to a sample part and perform a test. This helps verify that the gas delivery and fill process is working correctly and that tracer gas is reaching the internal volume as intended. It’s a valuable quality assurance step in maintaining the reliability of your sniffer test procedure.

Avoid Tracer Gas Contamination

After completing the sniffer test, make sure the tracer gas inside the part is properly vented outside the test area. This helps reduce residual gas contamination that could cause false positives and minimize sensitivity in subsequent tests.

Sniffer Testing Summary

The sniffer test is a reliable and versatile leak detection method used across industries for its precision, affordability, and ability to locate leaks directly. When using the helium sniffer test, operators benefit from one of the most sensitive and effective methods available for finding microleaks. Following proper testing best practices improves accuracy and efficiency, especially when implementing the helium leak test sniffer method in high-demand applications.

With the right equipment, operator training, and environmental controls, the sniffer test remains an essential tool in quality control and system integrity verification.

Need a Complete Leak Detection Solution?

Whether you’re setting up a new line or upgrading existing processes, we provide customizable, turn-key leak detection systems to suit your needs. Contact us to discuss how we can help streamline your testing operations with the right tools and expertise.