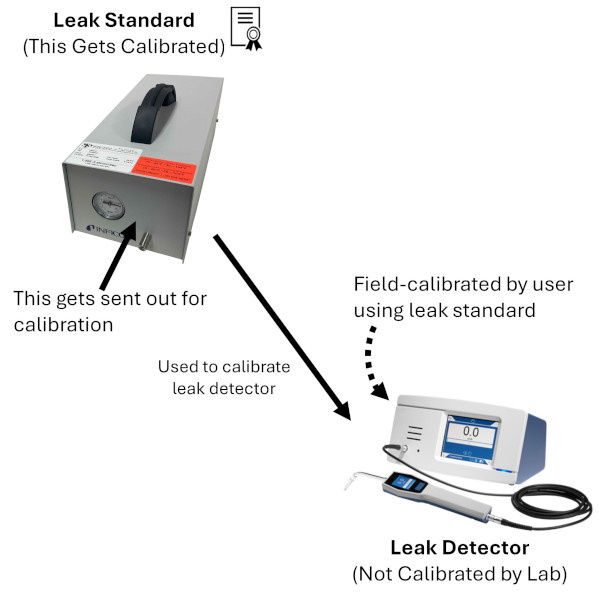

If you are wondering how to get your leak detector calibrated for reliable, traceable performance, you are not alone. One common misconception is that a leak detector should be calibrated by an accredited laboratory. In practice, it is actually your leak standard that is the certified item. In this article we will explain the function of a leak detector, a leak standard, and clarify why the accredited calibration applies only to the leak standard.

What is a Leak Detector

A leak detector is a device that detects tracer gases such as helium, hydrogen, or refrigerants. It may be part of a leak detection system in a manufacturing facility or a portable unit used in the field.

What is a Calibrated Leak Standard?

It is a device that leaks tracer gas at a precise rate. A calibrated leak standard is used to both calibrate and verify performance of a leak detector. Since this device must leak at a known rate, it is routinely sent in for calibration and receives a certificate of calibration from a trusted calibration lab.

Why is the Leak Standard Calibrated (Not the Detector)

The leak detector is field-calibrated by the operator using the leak standard. This calibration can happen as frequently as needed. The leak standard should be calibrated by an accredited lab to ensure traceability and accuracy.

When the standard has been calibrated, a calibration certificate will be supplied with the standard detailing the measured leak rate, uncertainty, and which traceable standards the calibration laboratory used to determine the leak rate.

Many organizations require calibration records to meet internal quality systems requirements or external standards such as ISO 9001. Because the calibration certificate applies to the leak standard itself, sending the leak standard for calibration helps maintain compliance.

How Are Leak Standards Used in Leak Detector Calibration

A calibrated leak standard is the reference tool used to set up and verify your leak detector. The process is generally straightforward:

- Enter the known leak rate from the calibration certificate into the leak detector.

- Run the detector’s calibration function, which adjusts the instrument to match the known standard.

- Validate performance by checking that the detector reads the leak standard within the expected range.

Depending on the equipment, this may involve contacting a sniffer probe to the leak element or connecting a calibrated leak to a vacuum chamber. Once complete, the same calibrated leak can be used periodically to confirm the detector is still measuring correctly. If readings drift too far from the certified value, the detector should be recalibrated.

Common Misconceptions

Misconception 1: I need to send my leak detector for calibration

Truth: Leak detectors are calibrated in-house by the operator using a leak standard

Misconception 2: The calibration certificate applies to my leak detector

Truth: The calibration certificate applies to the leak standard. The confidence and traceability of the leak standard is extended to the leak detection equipment when the leak standard is properly used to calibrate and verify the leak detector.

Misconception 3: Calibrations expire quickly

Truth: Most leak standards are calibrated every 12-24 months.

When to Recalibrate a Leak Standard

Most leak standards are calibrated on an annual basis although this can be extended further for lower risk applications. For applications with stringent leak detection requirements, stricter or more frequent calibration may be required. In regulated industries such as aerospace, medical device manufacturing, and safety systems, calibration frequency is usually established by internal procedures or external standards.

For a deeper look at calibration intervals, see our post Calibration Frequency

Accreditation & Trust (ISO 17025)

Our calibration laboratory is accredited by A2LA to the international ISO/IEC 17025:2017 standard. This standard is the benchmark for testing and calibration labs worldwide.

Accreditation means our methods, equipment, and record-keeping are independently reviewed by qualified auditors to ensure accuracy and reliability. By choosing an ISO/IEC 17025–accredited lab, you can be confident that your calibration certificates are valid for audits, compliance requirements, and quality system records.

Key Takeaway

It’s not your leak detector that gets calibrated — it’s the leak standard.

By sending your leak standard to an ISO/IEC 17025–accredited lab, you get:

- Traceability to international standards

- Compliance with audits and quality systems

- Confidence that your leak standard provides an accurate reference for your leak detector

Need your leak standard calibrated? Request a quote today