Calibrated Leak Standards Built to Your Specs

Precision-Calibrated Leak Standards for Any Application

At Spectro Physics, we manufacture a wide range of calibrated leak standards tailored for diverse industries and testing needs. Our standards support calibration, verification, and performance assurance across many applications.

Leak Detector Calibration

Used to calibrate automated and manual leak detection systems.

Establish Reject Limits

Ensure consistent pass/fail thresholds in production environments.

Verify Sniffer Sensitivity

Confirm sniffer devices are detecting leaks within spec.

Cross-Check Other Standards

Compare leak rates to validate third-party or in-house standards.

Built to Your Specs

Select your leak style, connection type, leak rate, and pressure.

Our calibration lab is ISO/IEC 17025:2017 accredited by A2LA, giving you full confidence in traceability, accuracy, and compliance. View Scope of Accreditation »

Leak Standard Types (By Tracer Gas or Application)

Looking for a specific type of leak standard? Explore our detailed pages:

Used to calibrate automated and manual leak detection systems.

Ensure consistent pass/fail thresholds in production environments.

Confirm sniffer devices are detecting leaks within spec.

Engineered leak standards built to match your part, process, and test requirements.

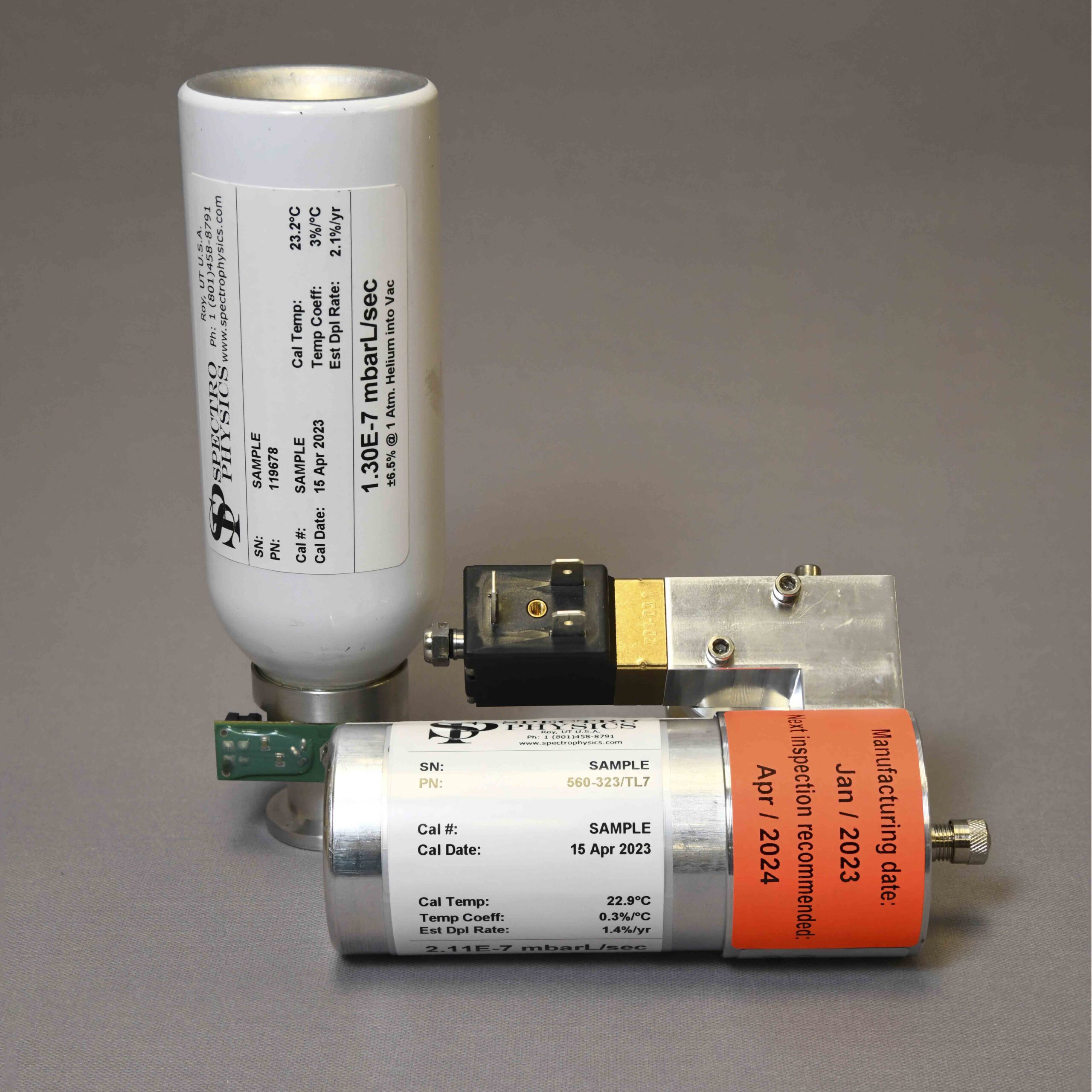

Reservoir Leak Standards

Reservoir leak standards are among the most widely used across the industry. These self-contained devices carry their own supply of tracer gas, making them ideal when a simple, autonomous, and consistent low leak rate is required. Reservoirs are sized to ensure minimal gas depletion over a typical one-year calibration interval.

They can be assembled with pressure gauges, isolation valves, or any connection fittings required for your application. Like other leak standards, they can be manufactured to custom leak rates and used to set or validate process reject limits. When parts can retain gas, they can be turned into reservoir leaks for on-demand validation. If not, we can design custom leaks that mimic the size and shape of your production parts for process verification.

Typical Applications:

- Calibration or verification of mass spectrometer and sniffer-type leak detectors.

- Use as a leak rate reference standard.

- Simulation of production parts in leak detection systems.

To see examples of different reservoir designs, visit our reservoir leak gallery (use the reservoir filter).

Open Style Calibrated Leaks

Open style calibrated leaks are ideal for applications where the user provides their own test gas under specific environmental conditions. These leaks eliminate the need for an internal reservoir, making them well suited for higher leak rates, integration into test fixtures or parts, or scenarios where a reservoir design is impractical.

Open style leaks are highly versatile and can be manufactured for nearly any gas type, leak rate, test pressure, or connection requirement. They are generally offered in two configurations: single-connection and dual-connection.

Need a custom solution? We can design an open-style leak precisely tailored to your test conditions.

Typical Applications – Single Connection Leaks:

- Pressure decay test validation

- Vacuum decay test validation

- Controlled gas release from a pressurized system

- Controlled gas input into a vacuum system

- Integrated into a part for calibration or validation

Typical Applications – Dual Connection Leaks:

- Simulation of leaking parts or components

- Validation of gas-charging processes

- Calibration or verification of mass spectrometer and sniffer-type leak detectors¹

- Use as a leak rate reference standard¹

View sample configurations of open style leaks in our open style leak gallery (use the open style filters).

Leak Calibration Services

We offer fast, A2LA-accredited calibration services for a wide range of leak standards — including those not manufactured by Spectro Physics. If you have a leak in need of recalibration or certification, send it in for a quick turnaround and reliable results you can trust.

See the range of configurations we’ve built — visit our Leak Standards Gallery for examples of open style and reservoir leaks.